How Do You Estimate Cycle Time?

Molders price jobs based on estimated press time, and that is where you can either be very profitable or lose your shirt. But there’s a new, free resource to help you out.

The best place to start answering the question posed in the title is to restate what I said in my January 2022 column:

Many of you know the age-old saying in our industry that that we don’t sell molded parts — we sell press time. That’s not entirely true. The fact is, we sell estimated press time, and that is where a molder can either be very profitable or lose his shirt.

At the very start of any project, before a mold is even built, or before a molder receives an existing mold from a customer, the parts need to be quoted. The question is, “Who does your quoting?” From my experience, most jobs are quoted by a project manager — someone who has a basic or, better yet, a good understanding of molds and molding. Someone who has been around the block a few times.

But I frequently see these experienced people getting on in age and eventually retiring to sunny Florida. Quoting is not something that’s taught in any school I know of. So, it is often up to the retiring expert to train their replacement. That rarely works out well, and usually ends up being a baptism by fire — at the company’s expense.

Molders sell parts based on estimated cycle times.

There are at least 14 different factors to be considered when estimating the cycle time. Instead of rehashing them here, they are well covered in my February 2021 column, “Get Better at Quoting Injection Molded Parts — Part 3.” Of those 14 factors, only the cycle time is an estimate and, all too often, a guesstimate. Even if a flow analysis is performed, the cycle time is still a guesstimate. While a flow analysis may be able to give a fairly accurate prediction of the required fill time and cool time, it cannot predict how well the mold, the machine and, in many cases, the operator, will function. It also can’t predict how well the process will be established on any given machine – especially an older model.

Therefore, the goal in quoting any injection molded part is to be very critical of the estimated cycle time and add a small percentage to cover any unforeseen issues without pricing yourself out of the job.

Quoting is not something that’s taught in any school I know of.

The overall cycle time of a mold is the combined times of the 11 components listed below.

- Mold-closing and lock-up time.

- Fill or inject time.

- Pack and hold (gate freeze or unfreeze) time.

- Screw delay or suckback before rotation time (pre-decompression).

- Screw recovery and plastication time.

- Screw decompression or suckback after rotation time (post-decompression).

- Cooling time.

- Cooling delay or idle time before mold-opening time.

- Mold-opening time.

- Part eject (and robot capture) time.

- Ejector (and robot) retract time.

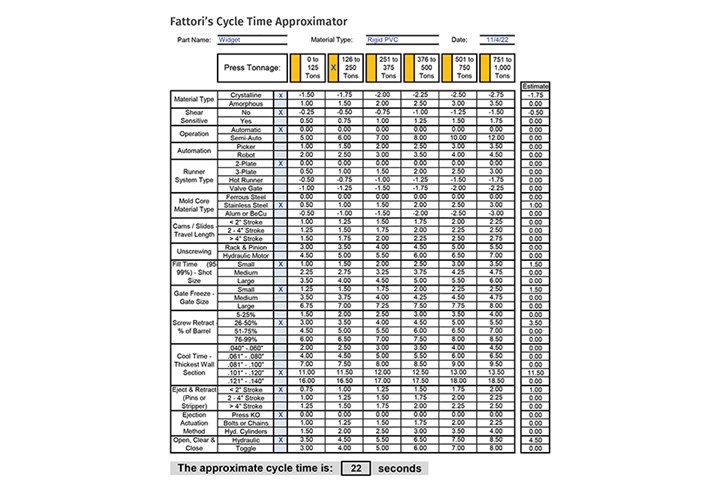

I don’t care how good you are, no one ever considers all these factors when estimating a mold’s cycle time. I never did. But I knew they were important. So, I spent a fair amount of time writing an easy-to-use Excel program to help me estimate cycle time. I offer this program for sale on my website.

But for various reasons, I’ve decided to share it with my fellow Plastics Technology readers — for free. After writing the program, I tweaked it by entering the values of dozens of existing molds with known cycle times. As a reality check, I then had a few processing friends of mine do the same. Is it accurate? In most cases it is very accurate — maybe ±15%, which is often much better than most guesstimates.

But you be the judge. You can start by clicking on this link to download the program.

ABOUT THE AUTHOR: Jim Fattori is a third-generation molder with more than 40 years of experience in engineering and project management for custom and captive molders. He is the founder of Injection Mold Consulting LLC in Pennsylvania. Contact: jim@injectionmoldconsulting.com;

injectionmoldconsulting.com

Related Content

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreImprove The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreRead Next

Get Better at Quoting Injection Molded Parts: Part 2

Follow these detailed tips to get you the injection molding jobs you want. Here we factor in the costs of scrap and regrind, along with energy and certain additives.

Read MoreGet Better at Quoting Injection Molded Parts: Part 3

Follow these detailed tips to get the jobs you want. This installment focuses on the mold and the molding machine.

Read MoreGet Better at Quoting Injection Molded Parts: Part 1

Follow these detailed tips to get you the jobs you want. This installment focuses on the various raw material aspects of quoting.

Read More