Molds & Tooling for Plastics Production

Molds and tooling for plastics production are used in all processes to give the melted plastic its final shape. Includes molds, mold components, ejector pins, mold bases, nozzles, mold cores, mold cavities, mold texturing, laser marking.

Narrow Your Molds & Tooling Search

ESSENTIAL READING

VIEW ALLWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

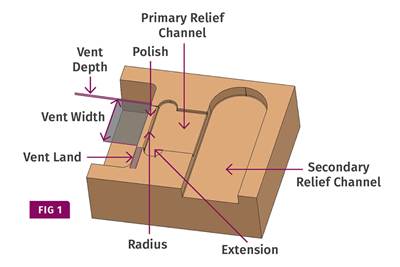

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreMold Maintenance, Tooling Know How

The ability of technicians in an injection molding shop to fix, modify or upgrade a mold has a huge impact on that company’s bottom line. With this collection of content, we’ve bundled some of the very best advice on repairing and maintaining injection molding machines.

Read MoreHow to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

Read MoreLatest Molds & Tooling News And Updates

NexGenSolutions, CAE Services Combine on Molding Simulation

Firms join forces to provide solutions and support for Moldflow users.

Read MoreMold-Channel Cleaning Equipment Gains North American Distributor

PCS Company is now offering Polish firm FADO Group’s CoolingCare system for automated mold-channel cleaning.

Read MorePressure Tester Checks Molds for Water Leaks

Globeius is offering the Mouldpro pressure tester for detecting water leaks within an injection mold’s cooling circuit.

Read MoreAIM Institute Adds Mold Maintenance Training Courses

The American Injection Molding (AIM) Institute, part of the Beaumont Family of Companies, will now offer mold maintenance training courses, following the acquisition of that business from Moldtrax.

Read MoreFakuma 2023: Configurable Control Units and Linear Actuators for Injection Molds

Servomold will introduce a new generation of control units for servo drives and a new series of actuators for the execution of linear movements in injection molds.

Read MoreHot Tip Sprue Cleaner Unclogs Sprue Bushings and Tips

Globeius’ Hot Tip Sprue Cleaner provides a flexible, hand-held tool for melting thermoplastics from plugged sprues and nozzles.

Read MoreFeatured Posts

Medical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

WatchWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreMold Maintenance, Tooling Know How

The ability of technicians in an injection molding shop to fix, modify or upgrade a mold has a huge impact on that company’s bottom line. With this collection of content, we’ve bundled some of the very best advice on repairing and maintaining injection molding machines.

Read MoreHow to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.

Read MoreFAQ: Molds & Tooling

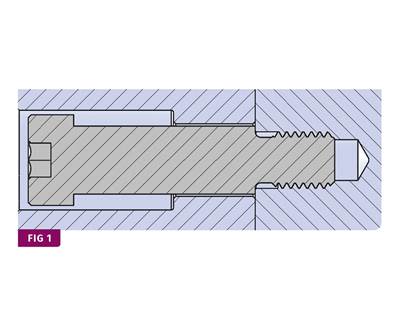

Leader pins are often referred to as guide pins. They lead or guide one-half of a mold into the other. The outer diameter of a leader pin is typically 0.0010 in. below nominal with a tolerance of +0.0000/-0.0005 in. A leader-pin bushing typically has an inside diameter of 0.0005 in. above nominal with a tolerance of +0.0005/-0.0000. Therefore, the pin has a close sliding fit in its mating bushing with a clearance of between 0.0015 and 0.0025 in. total. A close sliding fit is intended for the accurate location of parts that must assemble without perceptible play.

Molds & Tooling Supplier Categories

- Thermoforming Molds

- Blow Molds

- Nonferrous Metals for Molds

- Mold/Die Management Systems

- Injection Molds

- Mold Steels

- Cutting, Stamping, Trimming Dies

- Quick-mold-change Equipment

- Mold Making and Repair Equipment

- Mold Components

- Injection Blow Molds

- Rotational Molds

- Tool Engraving, Texturing Equipment

- Mold Evacuation Systems

- Mold Grease

- Rotational Molding Machines

- Compression/Transfer Molds

- Mold-cleaning and Maintenance Chemicals

- Nonmetallic Tooling Materials

- Hot Runner Components

- Foam Molds

- Compression/Transfer Presses

- Prototype Molds

.png;maxWidth=300;quality=90)