NPE2018 New Technology Focus: The ‘4.0’ Revolution

Injection and blow molding and robot suppliers are making Industry 4.0 the most prevalent theme of the show.

No single theme is likely to be more prevalent on the show floor than the “smart factory” movement known as Industry 4.0. Since makers of primary machinery, robots, and auxiliaries are all eager to show how they are becoming “4.0-ready,” only a few examples will have to suffice here. These examples address the three major elements of Industry 4.0: self-regulating “smart machines,” networked “smart production,” and web-enabled “smart service.”

In the “smart machines” category, KraussMaffei (Booth W403) is featuring its APC+ adaptive process-control software and DataXplorer software that provide a nearly microscopic look at the process.

In a similar vein, Engel (W3303) shows off the capabilities of its iQ weight control, iQ clamp control, and the U.S. debut of iQ flow control. There is also iQ vibration control to counteract robot shake.

Engel is also emphasizing “smart service” with the North American launch of its e-connect customer portal for 24/7 customer service, and newly developed e-connect.monitor for predictive maintenance.

Netstal (S16088) presents its new e-service program for access to machine-specific documents and spare-parts ordering. Also on display is the AnalytiX Cloud-based production-monitoring system, accessed via an app for smartphone or tablet.

Wittmann Battenfeld (W3742) is running HiQ-Melt, HighQ-Flow, and HiQ-Cushion “smart machine” technologies as part of its Wittmann 4.0 program. Since this firm makes both injection machines and a full range of auxiliaries, it has linked all these devices with the aid of a secure Wittmann 4.0 router. This makes it possible to store and recall all parameter settings for a job within the Unilog B8 machine control—automating setup of the molding machine, robot, dryer, chiller, TCU, and blender. Wittmann 4.0 is demonstrated on six work cells at NPE. One cell also shows the new Condition Monitoring System for predictive maintenance.

Milacron (W2703) is calling its Industry 4.0 program “M-Powered.” Its constellation of cloud-based tools includes remote tech service with augmented reality (see it at the booth), 24/7 remote monitoring and analytics, predictive-maintenance monitoring, real-time OEE (overall equipment efficiency) reporting, interactive technical manual, interactive parts catalog, and eSTORE.

Arburg (W1325) will present its take on Industry 4.0 with a demonstration of individualized manufacturing that coordinates different machines and processes. Business-card holders will be molded and laser marked with a barcode label that provides access to production data for that part from a remote computer. Then the part is custom decorated by Arburg’s freeformer 3D printer.

Nissei (W923) will show off its “Visualization of Factory” program for using the injection machine to pull information from connected devices, such as auxiliary equipment. One element is the “PQ Manager,” a quality- and production-management system that can monitor multiple machines.

Sumitomo SHI Demag (W3045) has implemented myConnect internet access for customers to receive online support, machine documentation, spare-parts ordering, and management of service and maintenance.

Boy Machines (W2503) is presenting its latest controller, Procan Alpha 4, which incorporates enhanced MES functionality and the OPC-UA communication protocol that is becoming a standard for Industry 4.0.

In blow molding, Nissei ASB (S19045) says its new ASB-12M v2 one-stage stretch-blow machine has an all-new control system designed to Industry 4.0 standards, allowing factory integration via the “internet of things.”

Likewise, Jomar Corp. (S12077) shows that it embraces Industry 4.0 with its new IntelliDrive injection-blow molders, whose controller collects machine performance data for remote monitoring via the internet. Its next step will be predictive maintenance.

Three robot suppliers at the show (in addition to Wittmann Battenfeld above) are putting particular emphasis on Industry 4.0. Yushin America (W2173) is introducing its FRA line of linear robots with a new E-Touch V controller that permits remote troubleshooting and predictive maintenance. Also new is the Intu Line Cloud-based service for providing production statistics and live camera feed for the molding cell via the robot control. Several FRA robots in various booths at NPE communicate their data to the cloud, where it will be displayed in the Yushin booth on smartphones and tablets. Yushin says FRA robots also can act as cell managers for all post-mold activities beside the machine.

Sepro America (W8571) is showcasing its “Open 4.0” program for integrating its robot controls with those of injection press makers, and its new apps for remote service (Live Support) and cycle optimization (OptiCycle).

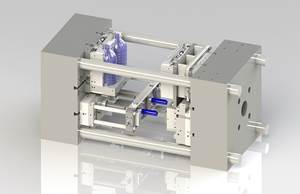

And Stäubli (W4003) is highlighting an “Industry 4.0 workflow” for fully automated injection mold changes.

One element of Industry 4.0 is communication of manufacturing data between machines and a central computer. Exhibitors of production monitoring, MES and ERP software systems include CyFrame (W393), Intouch Monitoring (S33188), IQMS (S20023), Oden Technologies (W8681), QT9 Software (S31124), SG Systems (W9413), ShopFloorConnect (S35057), Smart Attend (S10029), Syscon International (W4844), Syspro ERP Software (S30114), and T.I.G. (an Engel subsidiary; W3303).

Related Content

Honoring Excellence at NPE 2024: Plastics Hall of Fame

Yesterday, the Plastics Hall of Fame celebrated a legacy of innovation and vision for the plastics sector with 17 new members. Discover how these pioneers have helped shape the future of plastics.

Read MoreInfrastructure May Prove Big Landing Spot for Recycled Plastics

As the government funds infrastructure improvements, a hot topic at NPE2024 – exploration of the role recycled plastics can play in upcoming projects, particularly road development.

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreAt NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More

(2).jpg;maxWidth=300;quality=90)