Two New Blow Molding Tech Centers

Blow Molding

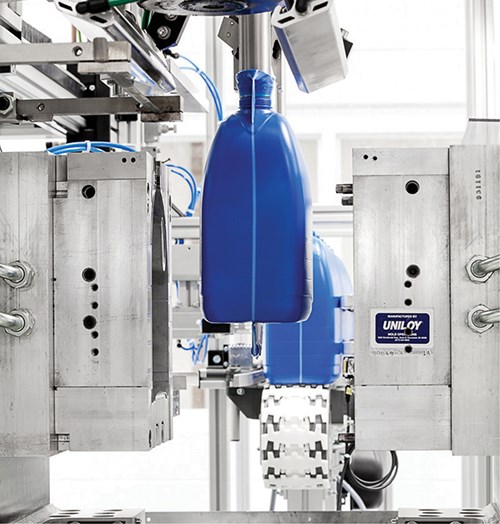

Uniloy offers a range of new and expanded services for extrusion blow and injection-blow molders.

Two recent announcements from Uniloy, div. of Milacron LLC promise a step up in training, development, and other services for blow molders. In May, Uniloy formally opened its greatly enlarged extrusion blow molding center and announced plans for another to open in the next few months for injection-blow molding.

BLOW MOLDING CENTER OPENS

The first event was the grand opening of Uniloy University at Uniloy North America’s headquarters in Tecumseh, Mich. Its 15,000 ft2 are dedicated to customer training, mold trials, and product and process development for extrusion blow molding.

Uniloy University has been fully up and running since February with three machines (versus just one previously):

• Model 350R2, a 90-ton model in Uniloy’s older, workhorse R series of reciprocating-screw extrusion machines that has been a standard in the dairy industry. It carries one or two heads for containers up to 5 gal/20 liters. It has electric screw drive.

• Model UR70, a 30-tonner in the newer UR series reciprocating-screw units. It’s a twin-head machine for up to 2-gal/8L containers, also with electric screw drive.

• Model UMS12E, 12-metric-ton, all-electric, continuous-extrusion shuttle machine from Uniloy’s B&W operation in Germany. It has a W. Muller head (standard on these models) with six vertical auxiliary extruders (plus the main extruder), providing capability for six-layer coextrusion with barrier, adhesive, and regrind layers, as well as a view stripe. The head allows moving the regrind layer from the inner to the outer portion of the structure with a simple switching of a valve. Its single head runs up to 10L containers. (W. Muller in Germany has a U.S. office in Agawam, Mass.)

Uniloy University also features a greatly expanded analytical lab for measuring container dimensions and wall thickness, as well as testing for drop impact and top-load strength. It has classroom facilities and new operator training courses are being developed for both the new UR Series machine and the 350R systems.

Other capabilities of the tech center are container design prototyping (as in the past) plus production feasibility studies, market-test runs of up to 20,000 bottles, resin trials, and product optimization. A new area of activity, notes Eric Hallstrom, sales manager for new business development, is original R&D, which has focused initially on sustainability initiatives like light- weighting designs and other resin-saving technologies. For example, Uniloy has recently worked with calcium carbonate supplier Omya Inc., Cincinnati, and masterbatch producer Heritage Plastics Inc., Picayune, Miss., to explore cost savings by substituting up to 7% fine-particle CaCO3 for more expensive HDPE resin in dairy jugs.

Tests also show energy savings (kW/lb) of up to 10% or more. Another sustainability project at the tech center involved testing biobased HDPE derived from sugarcane ethanol and supplied by Braskem America Philadelphia. Mike Kippnick, Uniloy global product manager and head of the tech center, says this “Green PE” runs just like standard material, but he envisions using up to 30% of it in dairy containers because of its cost.

North American sales manager Tim Tomlin notes that Uniloy University has the additional advantage of Uniloy’s mold-building operation located in the same building just next door.

NEW PARTNERSHIP FOR INJECTION-BLOW

A second major announcement by Uniloy was its new partnership to develop an injection-blow molding development center with Big 3 Precision Molds. They are establishing this tech center at Big 3 Precision’s Millville, N.J., moldmaking facility for injection-blow molds (which Uniloy itself does not make). For customer training and product/process development, the 1500-ft2 tech center will provide a GMP-certified, climate-controlled lab with two Uniloy injection-blow machines, supported by Uniloy technicians:

• The latest UIB 199-3 hybrid machine (180 tons) for monolayer applications.

• A smaller UIB 54-3 (45 tons) for multi-layer coinjection development.

Uniloy is putting special emphasis on adapting technologies from its Milacron sister companies, Mold-Masters, Kortec, and DME. For one thing, it is adapting Mold-Masters’ Axiom hot-runner technology and TempMaster hot-runner controller to injection-blow. Uniloy is also especially excited by the potential of harnessing Mold-Masters’ and Kortec’s coinjection technologies for barrier packaging in food and medical applications. These include not only special multi-layer injection nozzles but also Mold-Masters’ E-Multi electric-driven auxiliary injection units. Hallstrom calls this collection of technologies potentially “game-changing” for injection-blow.

The monolayer machine will have a 20-cavity test mold for 50/60 cc tablet bottles using Mold-Masters’ Axiom hot runner. For the coinjection system, Uniloy and Big 3 Precision are developing 20-30 cavity systems for barrier applications such as COC/nylon/COC and PC/nylon/PC. The two firms have already done prototype work and short-run production for the first commercial application of coinjection-blow technology.

Through this partnership, Uniloy will be offering turnkey injection-blow systems with single-sourcing of the machine, mold, hot runner, die set, and auxiliary equipment, all fully integrated and tested prior to shipment. Says Hallstrom, “We are employing the total systems approach that has been so successful for Uniloy’s intermittent-extrusion, reciprocating-screw technologies.”

Related Content

Services to Help Blow Molders Convert to rPET

Sidel launches “RePETable” range of services as “one-stop” solution to efficient adoption of rPET for bottle production.

Read MoreKrones Acquires Netstal

Krones adds PET preform injection molding to its bottle blowing and filling capabilities, as well as cap molding and expansion into medical, food and other markets.

Read MoreFirst Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

Read MoreAdding Remote Service Functions for PET Bottle Blowing

KHS has added features to its internet machine communications portal for PET stretch-blow molding.

Read MoreRead Next

Recycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More