Vacuum Venting Keeps Molds Running Longer

In tough economic times, facing hungry competition here and abroad, molders cannot afford to ignore preventable problems that slow cycles, cost machine downtime and mold maintenance, and waste material on reject parts.

In tough economic times, facing hungry competition here and abroad, molders cannot afford to ignore preventable problems that slow cycles, cost machine downtime and mold maintenance, and waste material on reject parts. One unnecessary drag on productivity is gas and air entrapment in the mold, which is not always cured by conventional venting approaches. That lesson was learned by Infinity Molding & Assembly Inc. in Mt. Vernon, Ind., a $15-million custom injection molder of parts for transportation, electronic, and medical markets. Infinity molds resins such as PPS, acetal, rigid PVC, PPA, LCP, PC, and PBT on 40 presses from 35 to 610 tons. Many of the parts are small and complex.

Poor venting can take a toll on the product and the process, says Joseph Crowdus, v.p. of technical services. “It can result in flashing, voids, bubbles, burn marks, and flow lines on the part. But more devastating is the potential for frequent production downtime for mold maintenance from contamination or tool erosion.”

In one case, Infinity was molding a thinwall battery component of clear, rigid PVC. “The parts were tiny, the shot size was 20 g, and we ran it in a multi-cavity tool,” says Crowdus. “The tool was vented in a traditional manner, but we had fits running the part. The vents weren’t able to fully evacuate air from the mold. Trapped air caused burn marks on the parts and short shots.” Infinity considered the option of slowing injection to make sure the mold vented adequately, but that caused short shots.

In addition, polymer residue remaining from the interaction with the trapped gas would build up and clog the vent channels after just a few days of operation, prompting a shutdown for mold maintenance. “Once the vent is clogged there is nothing you can do but clean the mold,” Crowdus says. Infinity breaks the mold down completely for cleaning and maintenance. The mold could be out of production from one work shift to an entire day, not to mention the off-spec parts made before production was halted.

VACUUM & AIR PURGE

To eliminate gas entrapment, Infinity purchased a Mold-Vac air/gas evacuation system from CAE Services Corp. The self-contained, stand-alone system pulls a vacuum on the vents during injection, and its patented air blowback function assists in ejection and helps clean and purge the vents and ejector pins after every cycle. “The blowback feature helps the tool to stay cleaner longer, and is a real benefit in extending time between cleanings. We run it on every cycle,” says Crowdus.

The microprocessor controlling both the vacuum and blowback functions receives a signal from the injection press then applies a vacuum that can be adjusted from 0 to 24 mm Hg. The system purges air at a rate of 0.02 cu in./sec, said to be the fastest in the industry. Vacuum and blowback operate on a timer setting programmed by the molder. Users mount the portable unit beside the press, position two limit switches, and connect vacuum tubing from the unit to the mold. The mold requires an air-tight seal. Infinity seals off a particular geometry in the part, or the entire mold, depending on the application.

With Mold-Vac, Infinity extended the time between maintenance shutdowns for the mold running the PVC battery part by a factor of at least two or three, which Infinity says is typical when it employs the device. Lower rejects are another benefit. Infinity has six Mold-Vac units and uses them with 10% to 15% of its active molds. “We use it with tough to vent applications” says Crowdus.

Related Content

How to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

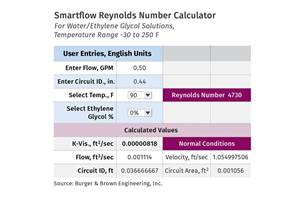

Read MoreCooling Geometry and the Reynolds Calculation

The original Turbulent Flow Rate Calculator worked well with a round circuit diameter, such as a drilled passage, but not as well using hydraulic diameters. Here’s how the problem was fixed.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More