Simulating Two-Shot Molding: How Does the First Shot Affect Overall Part Warpage?

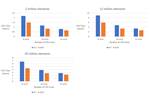

Moldex3D simulation can integrate analysis of the first-shot temperature, pressure, and fiber orientation into warpage analysis of the second shot.

In Moldex3D, fiber orientation in the first shot can be integrated into the warpage analysis of the second shot.

A new report from CoreTech System Co. of Taiwan, developer of Moldex3D molding simulation software, draws attention to some complexities of accurate warpage prediction in multi-component injection molding (MCM). The report, “Comprehensive MCM Simulation Considering the Previous Shot’s Effects” (short.ptonline.com/2-shot-sim), notes that the conditions of the first shot—especially molded-in stresses—affect part warpage behavior after the second shot. As the report states, first-shot effects on overall warpage behavior can be particularly important if the first shot contains fiber reinforcements, whose anisotropic orientation affects stress balance. Through the latest Moldex3D Warp Analysis, users can import the results of the first-shot analysis—including fiber orientation, temperature and pressure—into the second-shot simulation. Heat conductivity and thermal expansion of the first-shot material (as compared with the surrounding mold steel) are also taken into account. More accurate warpage prediction is said to result.

Related Content

-

Understanding Intensification Ratio

A first step in taking the “art” out of molding.

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

-

What to Do About Weak Weld Lines

Weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate.