Reciprocating Head Enables Profile-Shape Changes 'On the Fly'

NPE2024: Device eliminates the need to change tools to accommodate different profile shapes and eliminates assembly of the finished profile.

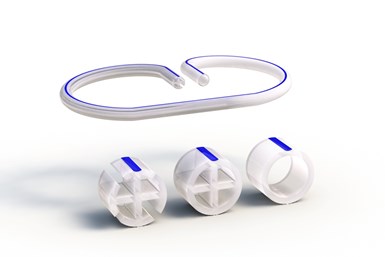

On the new reciprocating head developed by Guill Tool, the typical tip and die assembly is replaced with a linear reciprocating assembly that changes the tube’s profile on the fly within a given length. This process is repeated throughout a single extrusion run without interruptions. As a result, only one extrusion run is needed to produce a finished product, as opposed to multiple runs requiring tooling changes and manual assembly operation to connect different tubing shapes. Guill’s new reciprocating head also eliminates in-process inventory.

Source: Guill

This means there is no need for storage of various tubing shapes and connectors needed for assembly, fulfillment of orders and replenishment of finished goods.

Moreover, the reciprocating head eliminates a connecting piece, enables JIT production and products made-to-order, and reduces total run time from receiving the order to shipping, according to Guill.

Related Content

-

Online X-Ray Inspection Boosts Extrusion Quality

Höhle uses Sikora’s x-ray measuring systems for inline quality control of extruded microducts.

-

Radar-Based Wall-Thickness Sensor

Measurement units include an array of these sensors positioned around the circumference of the pipe, which can be placed in multiple locations on an extrusion line.

-

Green’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.