Injection Molding Machines Add Industrial IoT Service

Shibaura Machine says machiNetCloud provides users with secure, remote access to real-time machine data.

Share

Shibaura Machine, formerly Toshiba, a global supplier of injection molding machines, machine tools and die-casting machines, has launched the machiNetCloud industrial IoT service, giving users secure, remote access to real-time machine data.

Using remote access, authorized users and third-party vendors can monitor machines remotely and access data, enabling them to quickly respond to potential issues with a technician or spare parts. Shibaura says machiNetCloud can automatically alert third-party technicians and internal users by email and SMS.

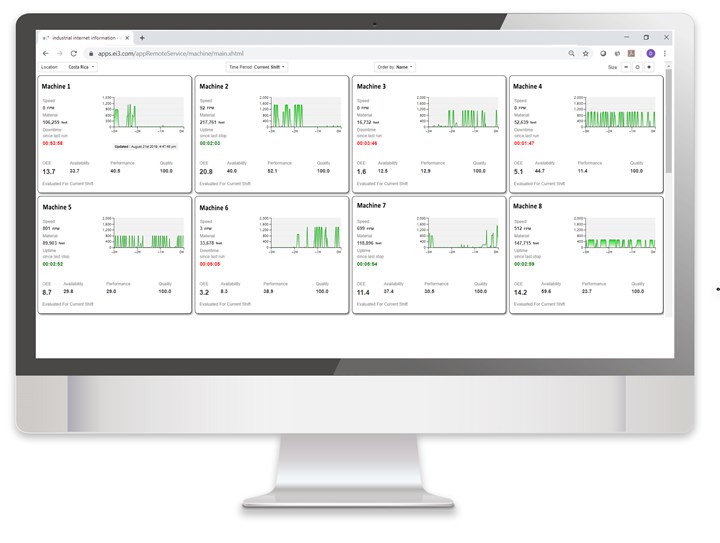

machiNetCloud features an intuitive customer portal, providing users with a suite of applications for reviewing key performance indicators. The program also automatically captures, analyzes and tracks machine downtime, helping users maximize overall equipment effectiveness (OEE) and calculate plant productivity. In addition to tracking downtime, the system offers real-time condition monitoring, historical performance and production analytics, as well as applications for managing quality, production recipes, energy usage and more. machiNetCloud is the first offering from Shibaura’s new Digital Services Div.

Shibaura’s new machiNetCloud IIoT service gives users secure, instant, remote access to key performance indicators. (Photo: Shibaura Machine)

Related Content

-

How Machine Monitoring Delivers Tangible Results

Much more has been said than done about reaping the benefits of data driven manufacturing among plastics processors. Good technology is essential, but change management is the most difficult part of the process. Here’s how to think about both.

-

AI-Based Injection Molding Assistant Launched

LS Mtron’s new AI Molding Assistant and Smart Weight Control technologies can help molders reduce costs while achieving higher quality and productivity.

-

Automation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.