EXTRUSION & COMPOUNDING: Five-Layer Film Structures Set to Supplant Three Layers?

In blown film, equipment and material suppliers have come together to push five-layer technology into non-barrier applications previously held by three-layer films.

In blown film, equipment and material suppliers have come together to push five-layer technology into non-barrier applications

previously held by three-layer films. Both Windmoeller & Hoelscher (whcorp.com) and Hosakawa Alpine (halpine.com) displayed five-layer lines aimed at collation film, silage film, heavy-duty sacks, and other types of industrial packaging.

Both machine builders ran lines featuring Exceed and Enable metallocene PE materials furnished by ExxonMobil (exxonmobilpe.com). For collation film, used to bundle water bottles, for example, the five-layer concept involves using a bulky HDPE core layer to stiffen the structure and provide better gauge control; thinner Enable subskin sandwich layers to further boost stiffness and shrink force; and Exceed-based skin layers to boost strength and impact resistance as well as optical and sealing properties.

Compared with three layers, five-layer systems are said to provide better film performance and line flexibility, as structures and material combinations can be tweaked to offer the desired properties. Five-layer structures are also said to boost output vs. typical three-layer systems because higher-melt-strength materials can be used in greater amounts. They also permit more downgauging.

ExxonMobil says this technology is still evolving, but machine builders at the show displayed equipment designed for it. W&H, for instance, modified its Maxicone die with the introduction of Maxicone P, designed for polyolefin processing. Alpine also ran a special version of its patented X die designed for these applications.

W&H’s line configuration featured five extruders—four 70-mm machines and one 105-mm, all with 30:1 LD—plus a 16-in. Maxicone P die and a single Opticool air ring whose spiral design offers air velocities of up to 180 mph. W&H produced 40-micron film at its booth and laid claim to a K Show record with an output rate of 2200 lb/hr (43.7 lb/hr/in. die circumference).

Alpine’s line consisted of four 65-mm extruders and a 90-mm machine for the core layer. All had 30:1 L/D. Running with a die diam. of approximately 12 in., the line pumped out 1700 lb/hr, or about 46 lb/hr/ in. die circumference.

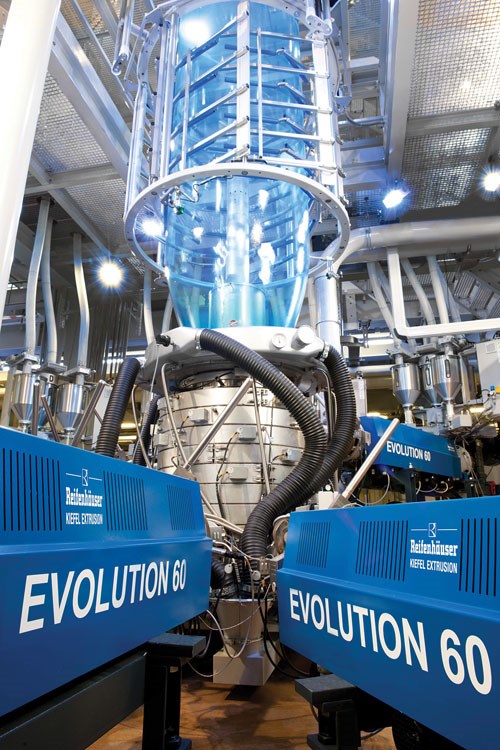

Reifenhauser-Kiefel (reifenhauser-kiefel.com) took another approach at K, running a nine-layer barrier structure. This represented the first public showing of the Evolution blown film line, a marriage of Reifenhauser and Kiefel technologies.

Davis-Standard (bc-egan.com) showed the ProCone die for up to nine layers. It is designed to allow for vertical movement of mandrels within the die stack. This allows for angular movement of the mandrels relative to each other, which provides the flexibility to change layer ratios without needing to change extruder position.

Parkinson Technologies (parkinsontechnologies.com) displayed its Genesis 700 center-driven duplex slitter/rewinder for small- to mid-size converting operations.

As reported in our September K preview, Brampton Engineering (be-ca.com) showed a streamlined FlexStack SCD (Streamlined Coextrusion Die) die. It is about half as tall of the supplier’s standard SCD, cutting residence and purging times. Macro Engineering & Technology (macroeng.com) showed a seven-layer TaperPack Die, the key component of its DXL-7000 Series of double-bubble lines. Addex Inc. (addexinc.com) displayed a simplified version its original autoprofile External Gauge Control air ring. Macchi (macchi.it) ran a nine-layer line that sandwiched barrier layers between layers of metallocene LLDPE and LDPE.

NANOS ARE IN

As reported in September, flat film and sheet toolmakers are focusing on nanolayer systems. Extrusion Dies Inc. LLC (extrusiondies.com) showed its “layer multiplication” technique, which relies on a special tool that can be engineered to multiply some or all of the layers within a coextrusion “sandwich” provided by a feedblock. Cloeren Inc. (cloeren.com) displayed nanolayer feedblock technology permitting structures up to 34 layers.

In sheet, PTi LLC (ptiextruders.com) debuted the Revolution series roll stack. This is a horizontal stack suited for processing materials with low melt strength. Davis-Standard (davis-standard.com) displayed its capabilities for PLA and PET sheet from 25 to 70 in. wide, 0.008 to 0.080 in. thick, with outputs to 7040 lb/hr.

Welex (welex.com) announced shipment of a versatile nine-extruder, multi-die system to an undisclosed European processor. The line will run a variety of products from monolayer to complex coextrusions. The dies are mounted on rails to permit them to move quickly in and off line for changeovers.

Gneuss (gneuss.com) launched a complete line for PET recycling, featuring its MRS 110 multi-screw extruder. The line is also equipped with an integrated cutter/feeder, Gneuss’ RSF Genius 150 screen changer, and an on-line viscometer.

NEW FLEXIBILITY IN PIPE TOOLING

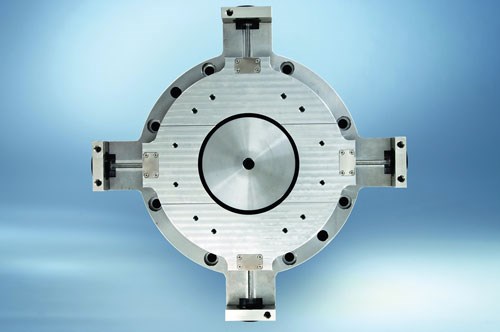

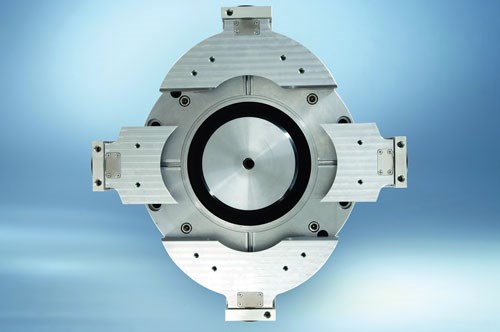

Inoex (inoex.de) rolled out new technology in PE pipe tooling that permits a wide range of sizes to be made with just one pipe head. The Advantage Evo Tool allows for two-stage orientation of the melt flow, which replaces the need to swap out dies and mandrels during a size change. Orientation occurs in the Maxxflex forming chamber, which is mounted between the die and calibration unit. Adjustments are made by a hydraulic drive. Changes to the melt flow inside the forming chamber change the dimension of the pipe.

Quick-change tooling was also shown by KraussMaffei-Berstorff (kraussmaffei.com). Its QuickSwitch extrusion system reportedly makes it possible to change polyolefin pipe diameter and wall thickness in minutes. At the touch of a button, the complete line changes automatically to the new dimensions, reducing the waste normally produced during changeovers.

KM-Berstorff’s newest universal pipe extruders feature a barrel with grooves in the feed section and “partial” grooves along the rest of its length, along with a shear/mixing screw that has a polygon geometry in the main plasticating zone. The supplier says the barrel design improves melt homogeneity, while the screw offers uniform mixing at low melt temperatures. The concept reportedly delivers 33% more output on PP pipe.

Cincinnati Milacron (milacron.com) showed FibrePlast, a raw-material preparation system for wood and natural-fiber composites of PP, HDPE, and PVC. The system utilizes high-intensity mixing technology for blending and then cooling and/or agglomerating the finished feed material.

As reported in September, Battenfeld Cincinnati (represented in the U.S. by American Maplan, maplan.com), showed a new series of parallel twin-screw extruders primarily for PVC profiles.

COMPOUNDING NEWS

In compounding, the ZSK Mc18 line of twin screw extruders from Coperion Corp. (coperion.com) features a 30% increase in specific torque—to 18 Nm/cm3—compared with other designs, and a 30% gain in throughput (see December issue).

KM-Berstorff exhibited a ZE 60 UTX twin-screw extruder for processing natural fibers and bioplastics. The machine features a processing section designed for high-volume or undried materials. For example, 6D-long barrel sections with large top openings assist in feeding and degassing low-bulk-density materials such as starch and cellulose ester.

Leistritz (leistritz.com) showed a new 18-mm twin with a 1.66 ID/OD ratio.

Davis-Standard (davis-standard.com) introduced a series of underwater, water-ring and air-ring pelletizers for normal, micro, and macro pellets in sizes for laboratories up to high-capacity resin plants. The redesigned die plates enable greater throughputs while nearly doubling the face life.

As reported in September, Gala Industries (gala-industries.com) showed its Model EAC (Electronically Adjusted) pelletizer for rates up to 33,000 lb/hr.

Related Content

Calculating an Injection Molding Machine’s Carbon Footprint

Arburg has utilized the ISO TS 1467:2018 standard, which determines the greenhouse gas emissions of a product, to help its customers calculate the product carbon footprint (PCF) of its injection molding machines.

Read MoreRecycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

Read MoreScaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More