Family Lumber Business Turns To Plastics

Five years ago, Quality Wood Treating in Prairie Du Chien, Wis., was a 30-year-old family lumber business and one of the largest wood pressure-treaters in the country.

Five years ago, Quality Wood Treating in Prairie Du Chien, Wis., was a 30-year-old family lumber business and one of the largest wood pressure-treaters in the country. Then founder Stephen Welter decided to get into wood-plastic composite decking. Not having plastics experience, he took a license in 1999 from Strandex in Madison, Wis., which offered a technology package for wood-filled HDPE extrusion that included know-how, machinery specs, and technical support.

By 2000, Quality Wood had started producing composite decking with three new ExtrusionTek Milacron E-80 conical twin-screw extruders and a blending and drying station from O.A. Newton. The Welters knew how to distribute their new product line, and in the first year they placed their EverX brand decking in local Home Depot stores. By 2001 they expanded capacity with three larger E-86 conical twin-screws to keep up with demand.

They were producing 10 million lb/yr with a workforce of 30. EverX decking first came in natural and gray with an embossed surface. Today’s color choices include cedar and redwood and “brushed” and “combed” finishes. The Welters also added balusters, posts, and railings to their product line

EverX contains over 50% wood flour (60 to 80 mesh pine). The fine particle size facilitates complete encapsulation with the plastic melt and better color distribution. Additives inhibit moisture absorption, which is only 0.7% in a 24-hr soak. Thickness swell is only 0.2% in a 24-hr soak.

Raising productivity

While Quality Wood was adding new machines, the company was also increasing output from existing lines by as much as 100%, says Gus Welter, Stephen’s son, who has worked with his father for 14 years since he finished college. Conair, which supplied the original downstream cooling equipment under the Strandex license, added more spray-cooling tanks to all of the original lines for higher output. Three tanks, instead of two, were placed after the larger E-86 extruders. Two tanks instead of one went after the smaller E-80 extruders.

Each Conair tank has an integral chilled-water cooling loop and independent temperature control. Profiling the temperature of the spray tanks cured a warpage problem in the 4 x 4 in. hollow sleeve that goes over pressure-treated wood to make structural posts. The hollow sleeve had a tendency to warp, which was corrected by cooling the sleeve more slowly.

Quality Wood redesigned its dies for higher throughputs and a change from 100% virgin HDPE to a mix of virgin and industrial recycle. The firm also added lubricants to raise throughputs.

Doubling again

The potential of the composites business was clear, but it needed more capital to grow. Quality Wood’s larger core business in pressure treating, while profitable, had a very thin margin and couldn’t generate the cash needed for the fast-growing decking operation. “To compete we had to grow,” Gus Welter explains. “That was outside the ability of a small business.”

In 2002, Stephen Welter decided to sell. He sold the wood lumber and explosively growing plastic composite business to Universal Forest Products (UFP) of Grand Rapids, Mich. He sold the pressure-treating plants separately a year later. UFP has nearly $2 billion in sales and 90 distribution centers.

After the sale, Stephen’s son Gus stayed with the composites business as operations manager. UFP moved the woodworking machinery, which had occupied half the plant, to other locations and added nine more extrusion lines—four of the smaller Milacron E-80 conicals and five of the large E-86 models. UFP also expanded the blending and drying capacity.

Now known as UFP Ventures II Inc., the company produced over 40 million lb of EverX decking in 2003 with a workforce of over 100 and continues to grow. Production this year is expected to reach 100 million lb. The company is considering setting up a new facility on the East or West Coast to save distribution costs and to add redundancy in case of a production outage.

Meanwhile, the original founder, Stephen Welter, stayed in plastic composites, too. He bought a pultrusion business in nearby La Crosse, Wis., where he is making structural and custom profiles.

Related Content

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

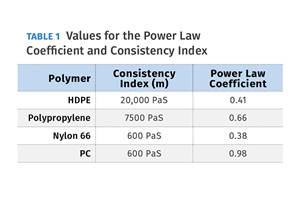

Read MoreThe Importance of Viscosity in Melting

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreHow Much L/D Do You Really Need?

Just like selecting the extruder size and drive combination, the L/D should be carefully evaluated.

Read MoreRead Next

Recycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More