Thermoformer’s Hot-to-Go Containers Enabled by Advanced PP Clarifier

Tray-Pak’s new custom thermoformed containers combine super clarity with high-temperature performance.

An additive technology that appears to have resulted in the first plastic food packaging to combine glass-like clarity and heat resistance has been introduced commercially by 41-year-old custom thermoformer Tray-Pak Corp., Reading, Pa. Tray-Pak, recognized as a pioneer and innovator in thin-gauge forming, teamed up with Milliken, Spartanburg, S.C., to create the new packaging. Tray-Pak’s sheet suppliers were asked to produce a PP homopolymer sheet utilizing Milliken’s new NX UltraClear PP concentrates.

Targeted to the growing demand for clarity, heat resistance, and increased sustainability in thermoformed food packaging—containers, clamshells, and trays—these concentrates are based on Milliken’s Millad NX 8000 fourth-generation nonitol-based clarifier, which has been shown to produce 50% less haze at any part thickness than previous benchmark clarifiers. Energy savings, lower emissions, and higher line speeds from lower processing temperatures are also claimed for this clarifier.

According to Milliken and Tray-Pak, supermarkets, convenience stores, and restaurants are looking for better ways to package hot and cold foods to capitalize on the increased popularity of fresh-prepared, takeout, and online ordering. The partners took on the challenge to come up with packaging that enhances the food’s visual appeal and stands up to hot-fill applications, heat lamps, and on-the-go microwave reheating.

Because the packaging is equally suited to hot and cold foods, it simplifies ordering and inventory management and reduces shipping and storage requirements. “With continuing growth in the $70 billion delivery/takeout market, especially in online ordering, the restaurant and catering industries are looking for packaging that can address multiple requirements—from increasing the food’s aesthetics and heat resistance to streamlining inventory,” explains Emily Blair, business-development manager for Milliken (milliken.com).

According to Troy Hill, Tray-Pak’s new-product development manager ,not only is there a “huge jump in clarity” with PP sheet containing NX UltraClear, but the additive’s intrinsic nucleating properties broaden the processing window—particularly important for more complex designs such as locking features.

Tray-Pak made the first commercial thermoformed food container in North America with NX UltraClear PP in 2015. Now it’s expanding on this success by offering several new designs using this polymer technology, including rectangular hot-to-go containers, a deli-wrap clamshell, and a single-cavity snack clamshell.

“We currently have 8- and 16-oz containers, but we are evaluating other sizes and containers with domed vs. flat lids for certain types of foods,” says Hill. The initial commercial foray was with a restaurant chain that wanted clear lids and bases, but the bases would also be tinted using Milliken’s ClearTint colorants. Brand logos are embossed in the tool, supporting further customization of the containers.

This novel packaging technology is allowing the veteran thermoformer, which has been serving the food-processing and food-service sectors, to enter new markets such as restaurant and grocery-store fresh-prepared foods, notes Hill.

Adds Ashley Brown, Tray-Pak manager of customer service and marketing , “Our initial packaging designs made with NX UltraClear PP have generated a lot of interest among our restaurant-industry customers, so it was an easy decision to move forward with development of these exciting new containers. Customers recognize the added value and logistical efficiencies they can gain by using packaging made from NX UltraClear PP.”

Related Content

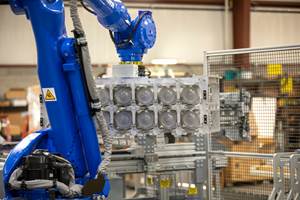

An Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreInteractive Training for Injection, Extrusion and Other Processes

Paulson has four in-booth stations demonstrating its various training solutions.

Read MoreNovel ‘Clamtainer’ Extends Thermoformer's Reach in Packaging

Uniquely secure latching expands applications for Jamestown Plastics’ patented clamshell package design.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More