Use Purging Compounds to Mitigate Processing Challenges of PCR and PIR

With frequent purging, you can minimize serious contamination issues and get both better results and higher profits.

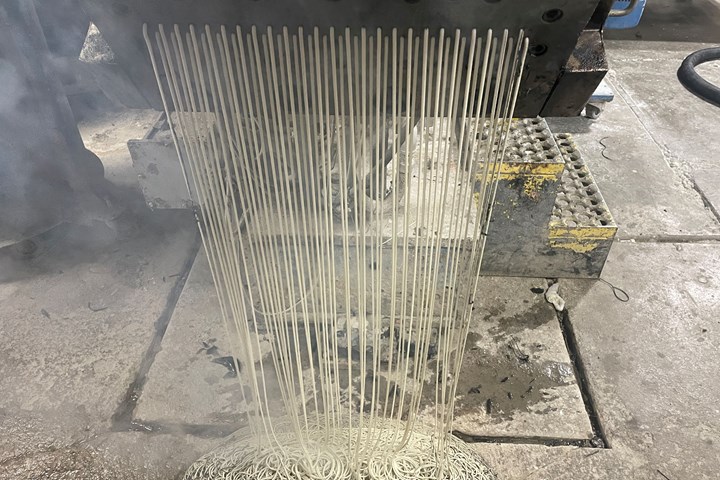

If contamination issues are severe enough to necessitate a screw pull, use of a specialty purge compound designed to peel easily off the screw. Source: Asahi Kasei Plastics North America

The adoption of postconsumer recyclate (PCR) and postindustrial recyclate (PIR) is a key element in the plastic industry’s significant transformation toward sustainability. While these materials offer substantial potential for reducing environmental impact, processors must grapple with contamination, variability and quality control to fully realize these benefits.

Purging compounds can play a crucial role in addressing these challenges. Whether it’s dealing with contamination issues, avoiding costly screw pulls or implementing proactive purging practices, the appropriate purging compound serves as a valuable tool in enhancing overall efficiency and cost-effectiveness. By embracing preventive purging best practices, manufacturers can overcome challenges and improve operational efficiency and product quality.

This article explores the pros, cons and challenges of processing PCR and PIR materials. It explains how purging compounds makes your shift to recycled materials more efficient and cost-effective.

Recycled Materials and Their Challenges

PCR and PIR materials are major components that have become pivotal in reshaping the industry’s future. Ten years ago, people used recycled materials to save costs. PCR can now cost you up to 40% more than virgin resins. Whether self-enforced or externally required, recycled plastics are here to stay.

Adopting recycled materials symbolizes a broader shift toward a circular economy — a paradigm that minimizes waste and maximally utilizes resources. PCR represents plastics once destined for landfills but is now given a second life through recycling. These sell at a premium because you’re giving new life to plastics already used in the market. Unfortunately, PCR usually originates from inconsistent feed streams. There’s a higher risk of cross-contamination of multiple resins (due to poor sorting) or inclusion of other contaminants.

Conversely, PIR encompasses the scrap generated during manufacturing processes, presenting an opportunity for efficient resource utilization. These are still recycled, but the market views them differently. Although the quality is usually much higher, market demand is lower for PIR because these materials have a different environmental impact. Customers value PIR because they achieve a more consistent product at friendly costs. These recycled materials contribute to the reduction of virgin plastic production, lowering greenhouse gas emissions and conserving valuable resources.

Whether self-enforced or externally required, recycled plastics are here to stay.

Integrating PCR and PIR materials into manufacturing has its challenges. Variability in quality, contamination concerns, degradation risks and complex processing needs are hurdles companies must overcome. An understanding of PCR and PIR materials’ unique properties and characteristics is important. While these materials hold immense potential for sustainability, their utilization comes with a set of distinctive challenges.

Working with PCR and PIR materials requires a comprehensive understanding of their origins and the quality of the streams. Unlike virgin resins, which follow a controlled manufacturing process, recycled materials inherit a history from their previous use. Thus, this history and the sorting process can introduce variations in composition and quality for which manufacturers need to account.

Although people typically assume PCRs are dirtier and PIRs are cleaner, this doesn't tell the full story. ‘Your source’ is just as important as the material category and you can have serious contamination issues in PIR and PCR alike. As such, it’s important to purge your machine often when using these materials to mitigate the likelihood of contamination.

Tackling Contamination and Frequent Screw Pulls & Teardowns

Removing contamination and improving teardowns are two crucial areas where purging compounds make an impact. Processors in molding and extrusion are no strangers to the frustration caused by black specs or gels — issues that cause their customers headaches, disrupting production and leading to increased scrap rates, reduced profits and missed deadlines. Moreover, recycled resins are prone to much higher contamination levels than virgin materials.

If you’re dealing with PCR/PIR-related carbon contamination, we recommend use of a high-performance purging compound. Purging compounds are not all created equal. There are now superior products available designed to tackle the unique contamination challenges presented by recycled plastics.

Working with PCR and PIR materials requires a comprehensive understanding of their origins and the quality of the streams.

In cases of severe contamination or prolonged equipment neglect, screw pulls may be necessary. Purging compounds can help in most situations and processors using high-performance purging compounds can expect to save upward of 65% when dealing with black specks and carbon contamination.

Sometimes, PCR/PIR contamination issues are so bad that you need to perform a screw pull/teardown. Suppose you're not using purging compounds to assist with screw pulls. In that case, your production stops in its tracks and your team can spend countless production and person hours on one aspect of production. This derails your profit potential.

We recommend the same product for teardowns for severe contamination as it has been shown to save countless labor hours spent cleaning the screw, enabling team members to work on other projects and to run more finished products.

For example, a recycler customer had to tear down the equipment for cleaning manually as regular purging proved to be simply not enough and their situation required a screw pull. Use of a recommended grade made its screw pulls much easier, safer and quicker with screw pull time reduced from five hours to 45 minutes.

The best offense is a good offense, so introduce preventive purging to avoid contamination issues and continue running good product. Source: Asahi Kasei Plastics North America

Preventive Purging Boosts Processing Efficiency and Profitability

We’ve covered black specks/gels and screw pulls/teardowns because they’re top of mind when people call purge suppliers. The first contact is usually reactive. But when dealing with PCR/PIR, it’s better to take a proactive approach. Preventive purging is a crucial component of any efficient preventive maintenance plan in plastics processing, especially when working with PCR and PIR. A proactive approach can significantly impact production efficiency and overall cost-effectiveness.

By focusing on optimizing machine performance, precision and high output become natural outcomes despite the difficulties associated with recycled materials. In plastics processing, waiting for contamination to appear before addressing it can erode profits. Processing costs encompass more than just the material costs; they also include startup time, scrap rates, machine downtime and more, significantly impacting the bottom line.

Proactive purging procedures are essential to optimize efficiency and profitability. Here are five preventive purging best practices:

• Listen to Your Data: If you're running the same material or color for a long time, you may think you don’t need to purge. Eventually, this mentality will hurt you. Try this: run your product until you start seeing contamination issues. Measure how many parts or throughput it took to get to that point. The next time you run, purge your system just before you experience problems during your test run. “On the fly" purging enables you to increase productivity with a clean machine.

• Don't Overdo It: It may sound counterintuitive, but purge experts such as those from Asaclean only want you to use what is necessary. The amount of purging compound required varies with each situation, and operators should purge until cleaning is complete, avoiding a preset amount approach. Avoid overusing purge to minimize waste. If you see diminishing returns, it would be understandable for you to investigate other options. Get the most out of your purge and get back to production.

• Purge Between Color & Material Changes: Whenever switching resins or materials, purging machines to eliminate previously run materials and safeguard against contamination in the next batch is vital. Although an extra step, it is more cost-effective than material waste resulting from rejects.

• Seal Machines During Shutdowns: To prevent contamination, seal machines with a thermally stable purging compound during shutdowns and extended downtime events like preventive maintenance. This step minimizes the risk of residual polymer degradation.

• Purge During Startups: At startup, extrude a sealing purge followed by one or two barrels of fresh purging compound before commencing production. This proactive approach efficiently removes contamination and carbon buildup, reducing startup time.

ABOUT THE AUTHORS: Tom Hanvey is product manager for sustainability & 3D printing for Asahi Kasei Plastics North America (APNA). Tom has worked for Asahi Kasei for eight years. From 2016 through 2023, he oversaw marketing for Asaclean Purging Compounds in North and South America. Hanvey is an MBA candidate at Indiana University’s Kelley School of Business and co-chairs the Asahi Kasei North American Marketing Council. Contact: 551-502-0680; tom.hanvey@akplastics.com.

Jeremy Berger is an application development engineer for Asahi Kasei Plastics North America in Fowlerville, Michigan. Jeremy has over seven years experience in the recycled materials space. His work focuses on the development of compounds using PCR and PIR. Contact: 989-293-3076; Jeremy.berger@akplastics.com.

Chris Melchiore is a business development manager for Asaclean Purging Compounds and a purging expert with over 30 years of experience with Nova-Chem and Asaclean. Melchiore is Asaclean’s premiere subject matter expert for all things extrusion. Contact: 203-437-9069; cmelchiore@asaclean.com.

Hank Moeller is a technical sales representative for Asaclean Purging Compounds. Before joining Asaclean, he spent his career working for Southeast U.S. injection molders. Contact: 803-675-4147; rmoeller@asaclean.com.

Related Content

Prices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

Read MorePrices of All Five Commodity Resins Drop

Factors include slowed demand, more than ample supplier inventories, and lower feedstock costs.

Read MoreCommodity Resin Prices Flat to Lower

Major price correction looms for PP, and lower prices are projected for PE, PS, PVC and PET.

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE 2024.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More

(2).jpg;maxWidth=300;quality=90)