Continuous Compression Molding Challenges Injection for Optical Parts

SACMI’s CCM systems, originally developed for bottle caps, now show promise for high production of lighting lenses and other optical parts.

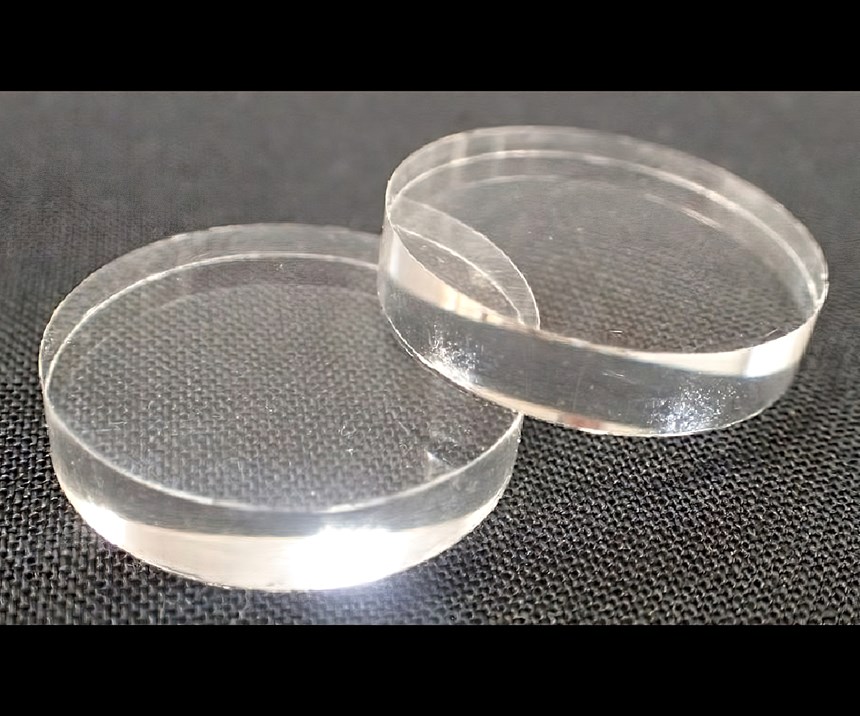

It’s not just for bottle caps anymore. Besides a recent move into single-serve coffee capsules, the continuous compression molding (CCM) process from SACMI of Italy is now being developed for optical parts such as lighting lenses, advanced instrumentation and automotive parts. SACMI is working with Polyoptics, a leading German producer of plastic optical systems and components, and the German research institute KIMW in Lüdenscheid. So far, the project reportedly has yielded excellent lab samples in cycle times significantly shorter than alternatives such as injection molding, says Sacmi.

SACMI builds CCM systems in which a plastic profile is continuously extruded and cut off into blanks that are automatically deposited into individual compression molds that move continuously on a conveyor. This process offers independent control of each mold and flexibility in number of molds being run. Lab tests have shown that CCM can use the same polymers—PMMA and PC—used by Polyoptics for injection molding of optical parts. KIMW verified the quality of the samples.

Related Content

-

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.