Engel Boosts Automation Production Capabilities in North America

The Austrian company held a ribbon-cutting ceremony to mark the expansion of its North American Automation Center in York, Penn., featuring 15,000-ft2 of production, office and logistics space.

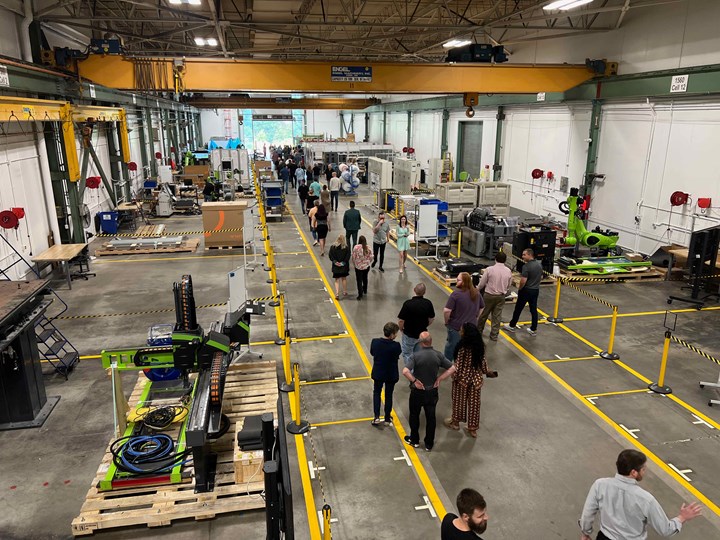

Engel North America has opened a new, expanded automation center at the company’s regional headquarters in York, Penn. Covering 15,000-ft2, the expansion will enhance Engel’s production capabilities, providing its customers a range of automation products and services.

Including production, office, and logistics space, the center came out of a renovation that began in August 2022 and doubled overall space. With 13 jobs running in parallel, Engel says the expanded facility has the capacity to complete 50 to 70 automation projects per year, focusing specifically on the U.S. market. The expanded center is staffed by a dedicated team of approximately 35 employees. Engel says the investment will allow it to provide shorter lead times, increased capacity and enhanced quality.

Engel touted the strong performance of its automation in the U.S. market, with more than $35 million in robot sales and the delivery of 350 to 400 robot and automation products to the country annually.

With a ribbon cutting ceremony held on June 7, Vanessa Malena and Stefan Aberl officially open Engel’s new automation center.

Photo Credit: Engel

Globally, Engel now has a network of four automation centers, with experience in everything from articulated robots and custom solutions, including degating stations, label systems, conveying, safety enclosures, feeding devices for insertions, quality inspection, cooling stations, end or arm tooling (EOAT), and assembly lines.

Vanessa Malena, president Engel North America, stated in a release that the company has a focus on automotive, technical molding and medical markets in the U.S. for automation, delivering complete UL-certified production cells that cover every aspect from conception, design, and manufacturing to start-up, validation, and after-sales service.

“With the costs of labor increasing; the scarcity of skilled labor; and the decreasing costs of robots; we firmly believe in investing in the future growth of this market,” Malena said. “Our new automation center positions us as a reliable partner, ready to support our customers’ evolving needs.”

The expanded automation center offers 15,000 ft2 of production, office and logistics space.

Photo Credit: Engel

Related Content

-

Drones and Injection Molding Ready for Takeoff

Drones and unmanned aerial vehicles (UAV) are approaching an inflection point where their production volumes — and functionality — will increasingly point to injection molding.

-

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

-

A Cost Saving Modular Approach to Resin Drying Automation

Whether implementing a moisture-sensing closed-loop system for a single dryer, or automating an entire plant, technology is available to take the guesswork and worry out of resin drying. Using a modular approach allows processors to start simple and build more capabilities over time.