Small-Footprint SLS Machine Can Operate in Where Space is Tight

A new Powder Recycling Station (PRS) is an optional accessory available in 2024 which works in tandem with the printer to automatically recycle unused powder currently in the system and mix it with fresh material.

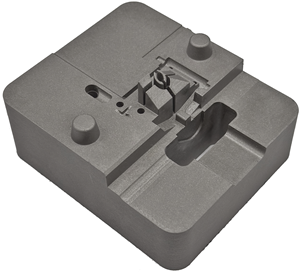

3D Systems has expanded its selective laser sintering (SLS) portfolio with the SLS 300, which is an affordable, turnkey, closed-loop system. The SLS 300 is designed to operate in a smaller footprint environment outside of a manufacturing floor, such as offices, material research labs or workshops. This makes SLS available to a broader range of customers with a high-reliability, affordable solution for the production of end-use parts.

The SLS 300 (formerly the Wematter Gravity) makes it possible to accelerate product development and in-house volume production with increased flexibility, lower risk, and reduced manufacturing and development costs. The system is an easy-to-install ecosystem that only requires a standard power source and an ethernet connection to be operational in less than an hour.

The system is well suited for prototypes, functional parts, small complex parts, parts for the automotive industry, medical supplies, pipelines and fittings for water pipes, and industrial components. The system is compatible with a broad material portfolio to address a breadth of applications. Users can produce tough, durable parts from a range of production-grade nylon materials. Choose from tough, impact- and fatigue-resistant nylon 11 materials or strong, or flame-retardant nylon 12 thermoplastics and filled nylons.

The patented packaging ensures users do not come into direct contact with any powder when filling the machine. The cylinders, made of sustainable paper and wood-based packaging, directly connect to the printer and fill it via a dedicated inlet on the front to keep the process dust-free. Each cylinder includes a QR card that helps ensure the correct material is loaded into the correct printer.

The system offers a new Powder Recycling Station (PRS) which is an optional accessory planned to be available in 2024. This unit works in tandem with the SLS 300 printer to automatically recycle unused powder currently in the system and mix it with fresh material. It enables the ability to use all material to maximize a user’s investment while lowering production costs and reducing demand for human intervention. The PRS includes HEPA filters and was designed with acoustic dampening which enables it to be used comfortably in a variety of environments.

The system simplifies SLS Technology with a plug-and-play format. This means users can print SLS-quality functional prototypes, tools and more without the need for specialized staff, investments in infrastructure and complex powder handling. The SLS also prints parts with mechanical properties as strong as injection molding without the need for complex infrastructure or expertise. It uses standard power, is low in office noise levels and requires no chiller or fume extractor.

This customizable 3D printing solution is available in two packages with optional accessories. The SLS 300 offers a 300 × 300 × 150-mm build volume at 10 mm/hr. It supports PA11 Black material. The SLS 300 Plus offers a 300 × 300 × 300-mm build volume at 12 mm/hr. It comes with an Essential Plus Toolset and supported materials include PA11 Black, PA11 Natural and PA12. Optional Accessories available with both the SLS 300 and SLS 300 Plus package include a Powder Vacuum and a Water Jet Cabinet.

Because of its patented packaging, users do not come into direct contact with any powder when filling the machine. Users can also work remotely, starting and monitoring print jobs remotely to increase productivity and resource consumption. The systems is easy to use with a simple user interface that guides operators through the end-to-end printing process to maximize uptime and productivity.

It also features an integrated touchscreen with contextual help guides. With the Wemote control panel, users can keep track of everything they need on a 13" inch touchscreen. An integrated camera enables operators monitor ongoing print jobs and shows estimated finishing time and status. Contextual help guides instruct users through steps such as loading the printer with new powder, cleaning the chamber or extracting finished parts from the build.

An Atmosphere Generator provides improved control of build chamber conditions in the printer for increased part density, surface finish and mechanical performance. It communicates with the SLS 300’s software to create a more stable thermal environment during the printing process.

The optional Water Jet Cabinet provides efficient depowdering. It cleans and extracts powder fast and conveniently using a water spray gun containing different nozzles to clean cavities, surfaces and smaller details. Built-in moisture control keeps a safe environment along with filters and sterilization for built-in water purification.

- Read about 3D Systems’ Accura AMX Resin which can withstands harsh thermal environments. The resin material is well suited for the testing of high-temperature components in applications such as HVAC, consumer appliances, motor enclosures, fixtures, mounts, stators, molding/tooling and more.

Related Content

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreMedical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

Read MoreProduction Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

Read More3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreRead Next

Recycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More

.png;maxWidth=300;quality=90)

(2).jpg;maxWidth=300;quality=90)