Hot Runner Nozzle’s Cable Location Shifted

Hasco has extended its Vario Shot nozzle range and optimized its cable location.

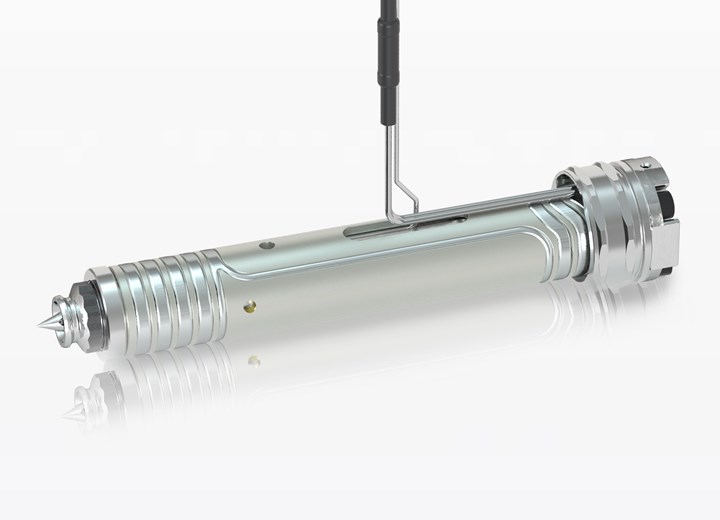

Hasco has expanded its line Vario Shot hot runner nozzles and developed a version where the cable outlet has been moved to the middle of the nozzle, relocating it outside the hot half in the nozzle retainer plate.

From a maintenance standpoint, this optimized cable location allows the heater to be easily replaced while the mold is in the press. In the case of multi-cavity hot runner molds or needle valve applications, processors will no longer need to dismantle the hot runner and remove the needle during service. Hasco notes that the hot runner nozzle’s thermocouple can be replaced from the parting plane. Through a strategically placed groove in the heater’s brass body, the thermocouple can be easily dismantled and mounted again.

Hasco has shifted the cable location for its Vario Shot hot runner nozzles, easing maintenance.

Related Content

-

Improve The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.