screws

Follow These Purging and Preventive Maintenance Tips for Your Screws and Barrels

Processors can extend the life of equipment and improve productivity by coupling a preventive-maintenance program for their screws and barrels with routine use of chemical purging compounds..

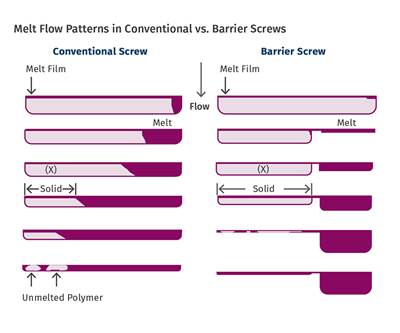

Read MoreScrew-Recovery Problems Call for Special Screw Design

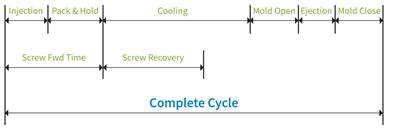

In injection molding, the penalty for using a general-purpose screw in an application that has special requirements often takes the form of longer cycle times. Barrier designs can help.

Read MoreWhat You Should Know About Miniature Extrusion Screws

Very small screws have become more common with the growth of additive manufacturing. Designing such screws requires balancing their output requirements with their torque strength.

Read MoreExtrusion: Important Polymer Melting Equations for Extrusion Processors

The more you know about what happens in a screw, the more you’ll be able to work with your supplier to optimize design.

Read MoreMilacron Renews Partnership With Barr for Screw Technology

Milacron has extended its exclusive partnership to offer Robert Barr Inc. designed screws on new Milacron injection molding machines or as aftermarket add-on to existing presses.

Read MoreNordson to Open Xaloy Tech Center in Ohio

Sixth new Nordson lab will open in Austintown, Ohio, at a newly built plant for Xaloy screws and barrels.

Read MoreExtrusion: Two-Stage Screw Offers Distributive, Dissipative Mixing

New design from Davis-Standard offers outputs comparable to barrier screws at lower melt temperatures.

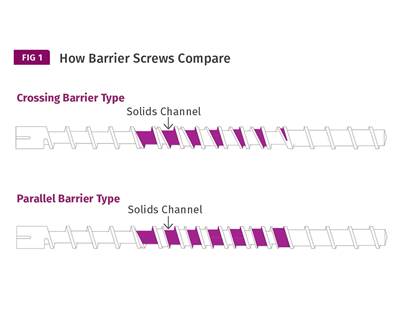

Read MoreBarrier Screws: Not All Are Created Equal

Let’s take a deep dive into parallel and crossing types and see where each fit in.

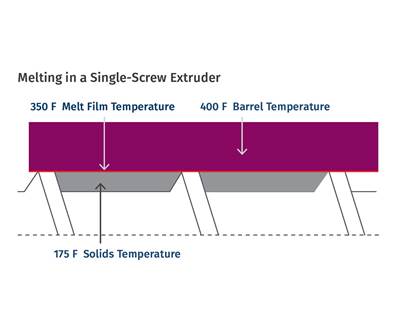

Read MoreWhy Barrel Temperatures Have a Small Effect on Melt Temperature

Extruders are not like ovens. Tweaking barrel-temperature profiles will not influence melt temperature all that much. Here’s why.

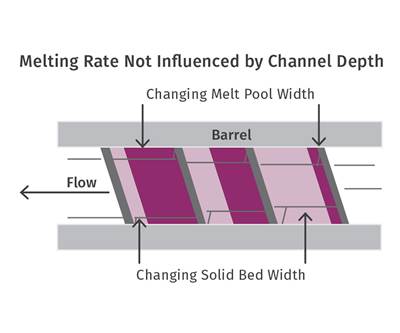

Read MoreSimple Scale-Up Calculations for Melting

You can avoid complicated melting equations when designing or evaluating a screw by using simpler methods that can save time and provide good results.

Read More

(2).jpg;maxWidth=300;quality=90)